Fringe Twisting

Fringe twisting is just one more step in finishing your weaving. And just like every other thing in the weaving process, you need to think about your fringe before the project ever gets on the loom. Let’s look at fringe generally first.

Why twist? The most important reason is because it looks nice and stays looking nice. An untwisted fringe looks great when it is freshly trimmed and pressed. After that the yarns begin to unravel, shred, tangle and, let’s face it, start looking a bit ratty. If you are making something for baby, a blanket for example, long thin threads can wrap around little fingers and cut off circulation.

Fringe twisting is just one more step in finishing your weaving. And just like every other thing in the weaving process, you need to think about your fringe before the project ever gets on the loom. Let’s look at fringe generally first.

Why twist? The most important reason is because it looks nice and stays looking nice. An untwisted fringe looks great when it is freshly trimmed and pressed. After that the yarns begin to unravel, shred, tangle and, let’s face it, start looking a bit ratty. If you are making something for baby, a blanket for example, long thin threads can wrap around little fingers and cut off circulation.

There are times you may decide not to fringe twist. Sometimes the yarn is so beautiful you want the colours to shine (I can’t bear to twist Handmaidens’ Maiden Hair) Or the fringe will look too heavy for the item. When I make loose gauzy mohair wraps, I don’t twist. And of course, there are other ways of finishing a fringe that don’t require twisting…various types of knots for example.

As I said earlier, fringe begins before the yarn goes on the loom. Fringe is made with the loom waste. That means when you are calculating warp you do not have to add extra for fringe but on the other hand, when you tie on, you want to leave enough waste to have the desired length of fringe. This is never and issue for me, I always have enough! Also, be sure that when you cut your work off the loom that you have left enough for fringe.

Having a fringe requires a hemstitch. Well, you could do it without a hemstitch, but it will look much better if you have hemstitched. So, when you hemstitch, think about how many ends you want in each bundle and hemstitch accordingly. Fingering weight I usually hemstitch in bundles of 4 and do a 2x2 fringe twist.

And now, what you have all been waiting for…the actual fringe twisting, step by step!

You will need: t-pins, something to stick your pins into (foam blocks work well) a ruler and sharp scissors.

1. Trim your fringe (remember that it will be shorter after twisting so don’t over trim) I use a rotary cutter and mat for this step.

2. It works best if you have your work anchored. Pin the edge of your work to the foam blocks…don’t skimp on the pins!

3. Clip the yarn into your fringe twister (I love my Leclerc quad) If I’m doing a 2x2 fringe I’ll take my first bundle of 4, divide it into 2 groups of 2 and place each group of 2 in one clip. With my quad twister I can do 2 bundles at a time.

4. Start twisting! Count the number of turns (this will vary depending on the yarn and the length of the fringe. Counting will ensure your fringe looks uniform across the work.

5. Hold the ends of 2 bundles and unclip. Tie a knot in the bottom and release. Gaze in awe as the yarn twists around itself.

6. After the first bundle is twisted, have a look. Is it twisted enough? Not enough? Do you like the length? Adjust as needed, then continue across the work . Repeat for the other side. Keep your ruler handy to make sure you are making the fringe the same length. Knotting a little higher or little lower can have a big impact!

7. Check to be sure the fringe is even and knots are tight. Trim close to knot.

You now have a lovely fringe that will keep your scarf, or blanket or table runner, or whatever you have woven, looking beautiful for years of use!

Dealing with Pesky Loose Ends

I’ve been working with linen lately. I’m finding it slippery, unforgiving, and tricky as warp! The first time I warped and tied on just as usual. Everything went well until the first time I wound forward. Everything went loose! Next time I paid extra special attention to winding on and checking tension. Again, everything was fine until I wound forward the first time and again, everything went loose. Third time I tried using 2 heddles. I think I need to practice more with 1 heddle before I try that again!

I’ve been working with linen lately. I’m finding it slippery, unforgiving, and tricky as warp! The first time I warped and tied on just as usual. Everything went well until the first time I wound forward. Everything went loose! Next time I paid extra special attention to winding on and checking tension. Again, everything was fine until I wound forward the first time and again, everything went loose. Third time I tried using 2 heddles. I think I need to practice more with 1 heddle before I try that again!

Loose threads are not the end of the world. Those loose ends can be fixed. Today I’ll give 2 of my favourite tips for loose threads.

Have you ever warped, tied on, then found when the heddle is in the downshed all the lower threads are crazy loose? I find this happens most often with warps with little to no stretch…cotton, linen, silk. First thing, be sure when you are winding and tying on all the threads are even in the heddle (slots and holes should be side by side).

If you’ve done that and you still have a problem it is super easy to fix. Place the heddle in the down shed, place a shuttle or pickup stick in the shed behind the heddle. Slide to the back warp beam. Slide the stick back each time you wind forward. Problem solved!

2. Sometimes there are just 1 or 2 threads that are loose. You can pay extra attention to those spots while weaving to be sure your shuttle goes over and under the troublesome ends or you can fix the problem for good. Simply hang an s-hook on the offending end and let it hang behind the back warp beam. You can add extra s-hooks to give extra weight as needed. I generally add s-hooks to the first and last end when weaving with cotton. I find it helps keep my selvedges tidy.

These 2 tricks mean I never need to deal with loose ends…and neither do you!

Happy Weaving!

Hemming

A good hem starts on the loom. I think about my hem before I ever start weaving. I want both hems to took the same so the first thing I think about is colour. If my weft is all one colour, it’s easy, my hems will be the same colour. If I’m using multiple colours, I need to choose a colour. If I’ve used a border colour that will become my hem colour. Otherwise, I use the darkest colour, or white no particular, reason, just because.

I make a lot of tea towels and dish cloths. That means I also sew a lot of hems! This post will take you through my steps to making hemming easy so those towels don’t languish in the “need to be finished” pile.

A good hem starts on the loom. I think about my hem before I ever start weaving. I want both hems to took the same so the first thing I think about is colour. If my weft is all one colour, it’s easy, my hems will be the same colour. If I’m using multiple colours, I need to choose a colour. If I’ve used a border colour that will become my hem colour. Otherwise, I use the darkest colour, or white no particular, reason, just because.

The next thing I think about is cotton weight. Most of my towels use 2/8 cotton doubled. For my hems, I use 2/8 single even if the main weaving will be 2/8 doubled. This makes for a lighter hem that does not add a lot of bulk. My sewing machine thanks me! When I use chenille or boucle or slub I will still use 2/8 cotton if I have the right colour. I also press my weft in tightly…usually 15 threads for each inch woven. I weave 2-2 1/4” per hem. I do not hemstitch my towels ever.

I never warp just 1 towel, I always warp for at least 2, sometimes 4. Usually 2 because I can get bored with 4! Doing more than one towel means I need to know the end of one and the beginning of the next. I just weave in 2 picks of a contrasting cotton.

When I take my work off the loom, I take it straight to my sewing machine. I sew a straight stitch at either end to secure the weft. Then I will sew a straight stitch on either side of the contrasting threads. I’ll cut all ends leaving 1” or so hanging and trim the extra warp again, leaving about a 1” fringe. I do not cut my towels apart yet.

Next, it’s bath time. Tea towels and dish cloths are meant to stand up to hard wear. They get thrown in hot water and soap for a regular cycle, then dried on high.

Next comes pressing, which can be a whole post on its own. Pressing is literally pressing the iron on the work, hold for 15 seconds or so then pick up the iron and move it to the next spot. Don’t iron as normal, sliding the iron back and forth across the work, as you may distort the weave (straight lines may become wavy). While pressing, trim all remaining ends flush to work and remove any remaining fringe. You won’t want to, but press both sides. Cut the towels apart by cutting between the 2 contrasting threads and remove those threads.

Now finally we get to the actual hem! Flip towel to wrong side. Turn end over about a ½” and press. Turn again and press so that the raw edge cannot be seen. I try to line up the hem so it just hits the beginning of the actual towel. Press firmly. Repeat for the other side of the towel, being sure you are working with the wrong side up. Make sure your threads line up, particularly at the colour changes.

Sew hem with a straight stitch and press once more. I love my walking foot for this task. Alternatively, you can hand sew your hem with 2/8 cotton. Give your towels a final press

Hemming is a lot of work, but a well sewn hem can make or break a towel.

Pick-Up Sticks will Explode Your World

I’m a big fan of plain weave. It is perfect for so many projects…hand painted warps shine, stripes in tea towels stand out and for a purely meditative weave, nothing beats plain weave. But have you tried pick-up sticks? They will explode your weaving world!

Pick up sticks weaving

I’m a big fan of plain weave. It is perfect for so many projects…hand painted warps shine, stripes in tea towels stand out and for a purely meditative weave, nothing beats plain weave. But have you tried pick-up sticks? They will explode your weaving world!

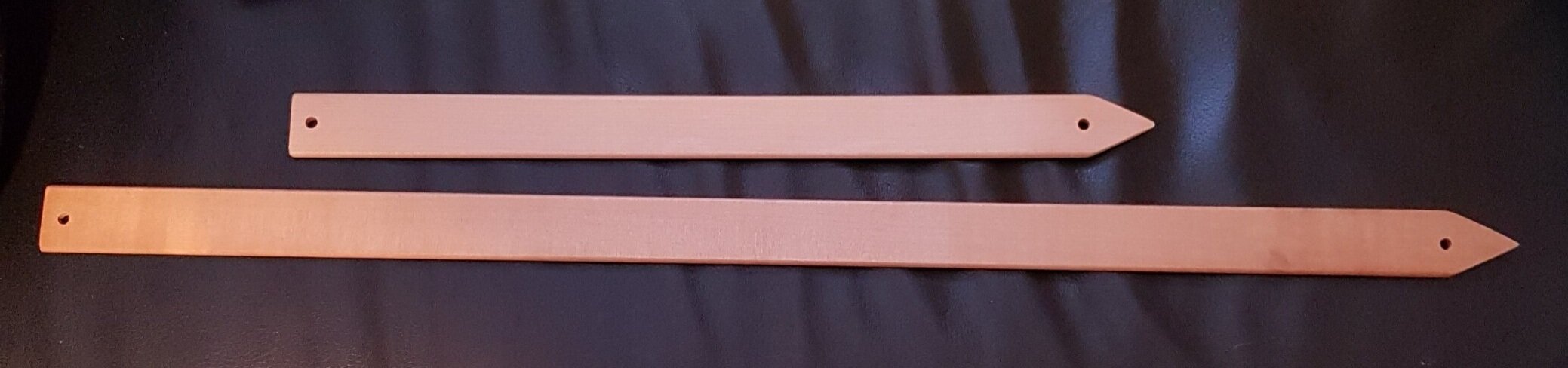

What are pick-up sticks? Essentially, they are just like stick shuttles except they have rounded ends, or a point. The pointed end makes it easy to pick up some threads and go under others. When inserted pick-up sticks create an extra shed (or 2) so it’s possible to do more than plain weave. (If you don’t have any pick-up sticks shuttles work too)

There are 2 ways to insert pick-up sticks.

1. Place the heddle in the down position, this brings all the ends in slots to the top. Stand behind the loom slide the point over and under the threads as the pattern directs. It might be over 1, under 1; over 2 under 1; over 5, under 5, or any other combination.

2. Place the heddle in the down position. Working in front of the reed place the pick-up stick as the pattern directs. Turn the pick-up stick on its edge to raise up the threads on top, slide a second pick-up stick under the raised threads behind the reed.

I always use method 1 but my books all use method 2. Method 2 works well for those with back or neck problems who don’t want to lean over the back of their loom. Here’s a video because it’s so much easier to see than write!

Sometimes it can be difficult to see exactly which threads to go over and under. If the warp is dark, slide a white piece of paper in the shed after placing the heddle in the down position. If the warp is light, use a dark piece of paper.

Now that the stick is in place you have 2 new sheds to use! (Remember the shed is the space the shuttle slides through).

Weft floats

1. Place the heddle in the neutral position. Slide the pick-up behind the heddle and flip it on its side. When the yarn goes through this shed you will see weft floats.

2. Place the heddle in the up position. Slide the pick-up stick behind the heddle leaving it flat. This will create warp floats.

And that is all there is to weaving with pick-up sticks! And this is only the beginning! You can use multiple pick-up sticks to create incredibly complex patterns. Patterns using only 1 pick-up stick are simple, the stick can stay in place the entire weave. With multiple sticks they usually need to be removed and replaced each repeat. That’s when you might want to start using string heddles. (But that’s for another post!)

If you think you’re ready to try pick-up sticks, here’s a link to a pattern I use to teach beginner pick-up weaving complete with video links. https://www.therogueweaver.com/new-products/malabrigo-waffle-weave-scarf

Happy Weaving!

New Year, New Weavers

Welcome to a New Year! From what I’ve seen on social media many are embarking on weaving! I know you won’t regret it!! As a weaving instructor I see many new weavers and weavers who want to improve their weaving. There is lots of advice I could give, but today I’m going to keep it short and sweet: don’t beat so hard! That’s it.

Welcome to a New Year! From what I’ve seen on social media many are embarking on weaving! I know you won’t regret it!! As a weaving instructor I see many new weavers and weavers who want to improve their weaving. There is lots of advice I could give, but today I’m going to keep it short and sweet: don’t beat so hard! That’s it.

This is a weft-faced fabric-meant to be dense with no warp showing

Experienced weavers know that what they see on the loom is not the fabric that will come off the loom and is not the fabric that will emerge after finishing. New weavers try to make the fabric on the loom look like the fabric they want when it comes off the loom. So they beat. Really hard. The weft is pressed so tight that nothing is getting through that fabric. When it comes off the loom and is finished a very dense stiff fabric results (and they have used way more yarn than they anticipated, or the pattern called for). I know this from personal experience!

Here’s the non-technical theory behind weaving. When you weave, the warp is under tension (stretched out). This allows the fibres to move up and down easily and create nice sheds for the shuttle. When the fabric (it’s actually called a web at this point) is cut off the loom, all the tension is released. So if you wove 80” on the loom, it might only measure 72” off the loom as the fibres go back to their natural relaxed state. This will vary depending on the fibre.

Weaving on the loom-note the holes

After you have taken the work off the loom, it takes a hot bath. This relaxes the fibres even more, and with agitation, fulling can occur. Fulling draws the fibres closer together creating a stable fabric. So now your 72” piece might only measure 65” (again, this will vary depending on the fibre)

In order for this to happen, the fibres need to have room to relax and move.

A ruler works too!

Here’s a couple tips to help you out:

1. Keep a tape measure handy. A balanced weave (good for beginners to practice) will mean that you have the same ppi (picks per inch) as epi (ends per inch). So if I am weaving a scarf on a 7.5 dent reed I should have 7.5 weft threads per inch of weaving. Check you work often with the tape measure. Especially when you are coming back after a break.

This is the same project as above after finishing-no holes!

2. Pay attention to how you draw your heddle forward. If the heddle is tilted towards you, you cannot see the weft being pressed into place. If you tilt it a little away from you, you have a great view of what is going on and have a little more control. You should be able to see through your work easily. Here’s a little video https://www.instagram.com/tv/CI6xZN-JWLQ/?utm_source=ig_web_copy_link

I hope this is helpful to the new weavers out there! Follow me on facebook or Instagram to find out when new blog posts are out. This year I plan to cover some beginner tips (things like edges, pick up sticks, and project planning) as well as delve deep into double heddle weaving, and, just because I can’t control myself, there will be some inkle weaving, tablet weaving and floor loom weaving. I’d also love to cover topics you are interested in, so if there is something you are looking for, please let me know!

Mohair for Warp?!

I’m on a few weaving groups on Facebook as well as following a number of rigid heddle weavers on Instagram. As I read the posts I learn a lot, some I agree with, some not so much. One idea that seems to be coming up a lot lately is mohair. Specifically, that one should not use mohair for warp. I must disagree!

I’m on a few weaving groups on Facebook as well as following a number of rigid heddle weavers on Instagram. As I read the posts I learn a lot, some I agree with, some not so much. One idea that seems to be coming up a lot lately is mohair. Specifically, that one should not use mohair for warp. I must disagree!

I know why weavers believe this, I’ve experienced why weavers, after 1 attempt at a mohair warp swear never again, but I love the effect of a mohair warp. I love the light airy feel. I love the drape. I love the warmth. I love how far just a little bit can go. So, here are my tips for using mohair as warp, and a free “pattern” to make your own mohair wrap.

Use the right hedd!e. Mohair is sticky. If it is too close together you will have problems. I usually use my 7.5 (for 1000m/100g) or 5 dent (500m/100g)

Place an extra shuttle or pick up stick behind the reed as follows: with heddle in the down position place shuttle in the shed behind the reed. Slide shuttle as far back as possible. This shuttle will stay in the work for the entire project. I find the down shed is usually the stickiest. The shuttle helps and if it is too sticky and you can’t get a clear shed: just slide the shuttle forward, flip it in its edge and voila!

Be prepared to spend extra time. Weaving with mohair does require a little extra patience. You will need to check to ensure the shed is clear before passing the shuttle through. You will probably spend time hand picking some threads apart. You may need a few s hooks to help with tension issues. You will need to be extra vigilant to ensure the right number of picks per inch.

After winding the work forward, place the heddle in the up position and spend a few minutes making sure there are no tangles behind the reed. This will make it easier to keep the up shed clear until you wind forward again.

Finally, have fun, try some lace or finger techniques. Mix and your warp, most of all, don’t be afraid, it is after all, only string!

I promised a free pattern. It’s not really a pattern because it is so easy, but here it is:

You will need a 7.5 dent reed and a mohair and silk blend (I use Zambezi by Fleece Artist/Handmaiden but Rowan Kidsilk Haze will work just as well. (Or any other mohair silk blend that is 1000m/100g)

Warp measures 100” (2.5 meters) Warp as wide as you like or your loom can handle (1000m will warp and weft 100” x 32”) Tie on in small bundles. I like to tie little bows because they are easier to untie at the end. Plus, they are so darn cute!

Weave at about 6 picks per inch. It really looks like a window screen as you are weaving!! (remember the tips above)

Hemstitch the ends in bundles of 4, alternatively, or if you forget to hemstitch, knots in bundles of 4 look like little beads (ask how I know!) Don’t worry about the spaces between bundles…they will wash out, I promise!

Weave until you can weave no more (about 84”)

Cut off the loom and tie fringe in large loose bundles to prevent tangling. Soak in very hot water (I use my washing machine). Spin out the water and dry on high heat for 5 minutes. Untie bundles and press with a hot iron set for steam. Trim ends and enjoy!

PS If you would like to order an already made wrap, please contact me!

The Magic of Finishing

I just finished a project this weekend. The whole time I was weaving I was feeling a little disappointed because it just wasn’t looking the way it ought. I was weaving a traditional hounds tooth pattern for the first time. But the hounds tooth wasn’t looking properly toothy. In my head I knew that once it came off the loom and was properly finished everything would be fine but my eyes were having troubles believing.

Still on the loom…not at all toothy!

I just finished a project this weekend. The whole time I was weaving I was feeling a little disappointed because it just wasn’t looking the way it ought. I was weaving a traditional hounds tooth pattern for the first time. But the hounds tooth wasn’t looking properly toothy. In my head I knew that once it came off the loom and was properly finished everything would be fine but my eyes were having troubles believing.

When a weaver uses the term “finishing” it doesn’t necessarily mean that the project is complete. Finishing (also called fulling) refers to the process of washing/soaking and drying the fabric to allow the fibres to plump up (full) and pull together (this isn’t technically accurate, but a very simple explanation of what it looks like happens). It gives the fabric stability and structural integrity. And it’s a little bit magical. Suddenly a loose weave that your fingers can easily poke through become fabric. A pattern that couldn’t be seen on the loom appears. And reed lines disappear

When I look at my weaving on the loom I can usually see right through the fabric. If the fibres are pressed too tightly in the weaving process then during the finishing process, when the fibres try to move, there is no space and the resulting fabric is very dense and thick. (I discovered this on my very first project). There are times when you want your weaving to be very tight (when making a rug for example) but usually at least a little bit of drape is desired.

When I finish a project I take it off the loom and straight to the washing machine. I fill the tub with hot water, add a little bit of eucalan and agitate just long enough to mix the eucalan. I then very gently add my project and push it under the water to make sure it is fully submerged. Then I leave it alone for about 1/2 hour just to soak. After the 1/2 hour I run the spin cycle. (At no time is the project actually agitated, only soaked and spun—unless I’m using cotton, then I run a regular hot wash cycle) I take it from the washing machine and throw it in the dryer and dry for about 10 minutes. Sometimes it takes a little longer than 10 minutes to get the density I want and I’ll give it a few more minutes.

In the case of my houndstooth scarf, it took 20 minutes in the dryer. Everything pulled together. The teeth are toothy, the scarf is drapy and it was so soft my daughter couldn’t keep her hands off it!